NON-DESTRUCTIVE AND DESTRUCTIVE TESTING LABORATORY

The Laboratory has the highest quality research equipment from leading manufacturers, which is regularly modernised and supplemented with the latest machines. All testing equipment and control and measurement instruments are calibrated acc. to the equipment used by PCA-accredited laboratories. Our team has long employment history and experience gained during the performance of contracts in industrial and power generation plants, carried out both in Poland and abroad.

The Non-Destructive Testing Laboratory renders its services at the highest level acc. to valid standards and strictly respecting requirements of the PN-EN ISO/IEC 17025 standard.

Non-destructive tests are performed by personnel certified acc. to:

- PN-EN ISO 9712:12 by UDT-CERT,

- Welding Institute,

- TÜV SÜD Industrie Service GmbH, level II and III.

The Testing Laboratory is approved by the Office of Technical Inspection UDT – LBU285/9-15 acc. to PN-EN ISO/IEC 17025. Approved testing methods include:

- Ultrasonic methods (UT) – defectoscopes and thickness measurements,

- visual tests (VT),

- penetration tests (PT),

- magnetic particle inspections (MT),

- hardness measurements by dynamic method (HT),

- leak detection tests with underpressure method,

- determination of chemical composition by X-ray spectrometry.

The Laboratory is also qualified and certified to perform the following tests:

- X-ray tests (RT),

- destructive tests for metallurgical products and welded joints,

- static tensile tests,

- impact tests,

- static bending tests,

- hardness tests,

- break tests,

- macroscopic testing,

- microscopic tests with optical microscopes.

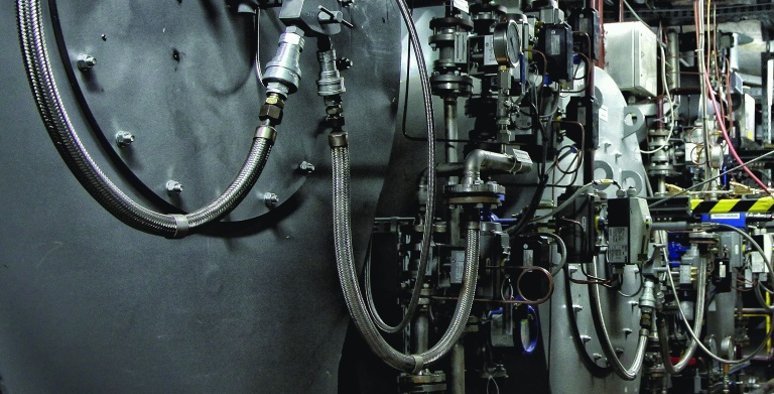

Gas Department

Gas Department

Cogeneration Department

Cogeneration Department

BOILER DEPARTMENT

BOILER DEPARTMENT

PIPING DEPARTMENT

PIPING DEPARTMENT

Construction Department

Construction Department

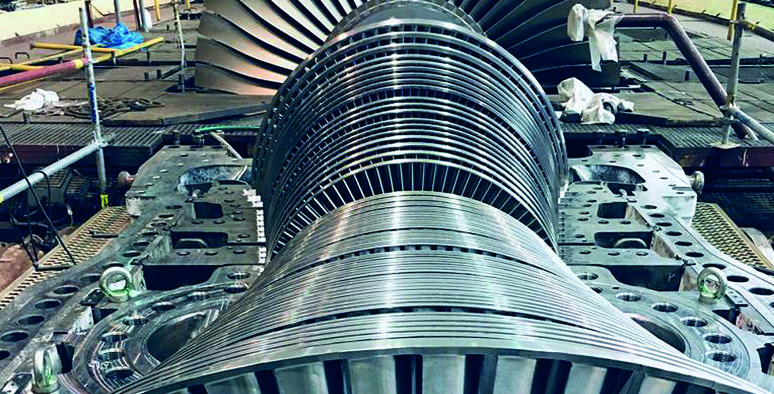

Turbomachinery Department

Turbomachinery Department

EPC Department

EPC Department

Heat Treatment Department

Heat Treatment Department

Export Department

Export Department

Department For System Commissioning

Department For System Commissioning  Department of Hydraulic Vertical Lifting System

Department of Hydraulic Vertical Lifting System  Non-Destructive and Destructive Testing Laboratory

Non-Destructive and Destructive Testing Laboratory