DEPARTMENT FOR SYSTEM COMMISSIONING AND WARRANTY HANDLING

The Department for System Commissioning and Warranty Handling carries out broadly-understood works related to the commissioning and optimisation of industrial systems. Our competences primarily include:

- development of an individual commissioning project as well as complete commissioning documentation including operating instructions,

- coordination of cooperation between the investor and contractors,

- acceptances upon erection of systems in all industries,

- the so-called “cold start-up“ – functional tests confirming the proper operation of process systems conducted prior to the introduction of process fluids and performed without load,

- the so-called “hot start-up“ or regulation start-up – tests performed after the “cold start-up“ that involve the use of process fluids and are performed under load,

- cooperation with design offices during the development of technical or process solutions that enable optimal high efficiency and capacity to be reached

- optimisation of operation of individual equipment and the entire system,

- performance of a test run confirming the readiness of the system for continuous operation,

- engineering support during the warranty period and post-warranty service.

In 2019, the Commissioning Group of REMAK-ENERGOMONTAŻ S.A. successfully completed the commissioning of a new eco thermal system with a power of 25 MWt fired with wood chips for MPEC Olsztyn. The system mainly includes:

- water boiler with a nominal power of 25 MWt and with an overhead grate,

- system of heat recovery from flue gases with a nominal power of 4 MWt together with a condensate treatment system,

- storage and fuel handling system based on movable floors and belt conveyors,

- dedusting system with bag filters.

In addition, the Commissioning Group has conducted works connected with the commissioning, regulation and operation optimisation of:

- new grate boiler type WR-40 fired with coal – Polkowice HP,

- new flue gas desulphurisation system based on semi-dry technology incl. auxiliary systems – Polkowice HP,

- new flue gas denitrification system based on SNCR technology together with a system for unloading and storage of the reagent – Polkowice HP,

- new power generating duo block with a capacity of 29.5 MWe located in the Częstochowa Nowa Coke Plant fired with coke oven gas.

Gas Department

Gas Department

Cogeneration Department

Cogeneration Department

BOILER DEPARTMENT

BOILER DEPARTMENT

PIPING DEPARTMENT

PIPING DEPARTMENT

Construction Department

Construction Department

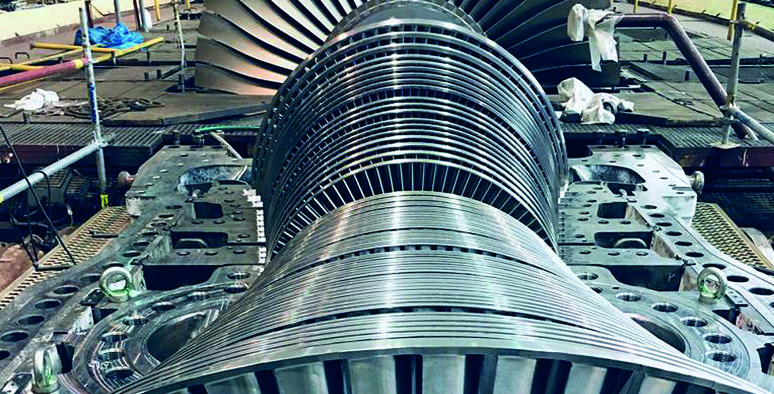

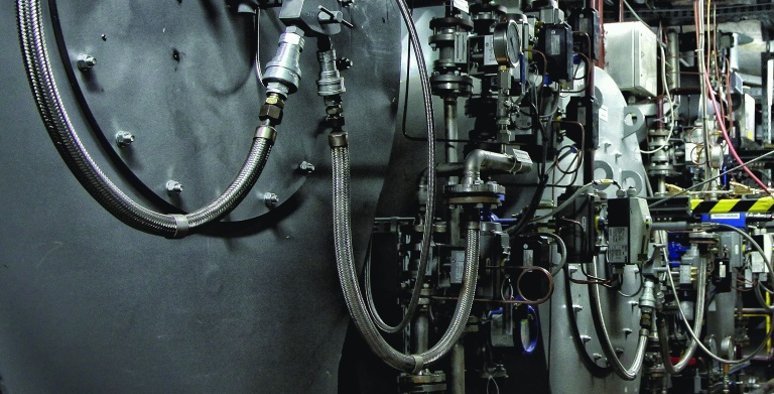

Turbomachinery Department

Turbomachinery Department

EPC Department

EPC Department

Heat Treatment Department

Heat Treatment Department

Export Department

Export Department

Department For System Commissioning

Department For System Commissioning  Department of Hydraulic Vertical Lifting System

Department of Hydraulic Vertical Lifting System  Non-Destructive and Destructive Testing Laboratory

Non-Destructive and Destructive Testing Laboratory